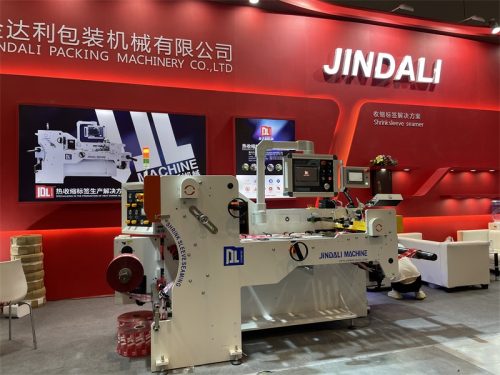

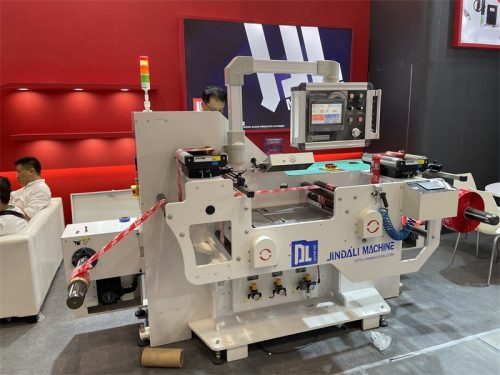

F450 High Speed Shrink Sleeve Seaming Machine - Template free

The high-speed shrink sleeve converting equipment is used to form PVC and PET heat shrinkable film materials into roll bag packaging materials, such as shrink sleeve labels for beverage bottle, shrink sleeve labels for aluminum can, shrink sleeve labels for wine, etc.

System Function

Automatic unwinding tension

Automatic memory curve winding tension

Automatic glue supply control

automatic meter counter

The roll diameter reaches the stop

Unwinding correction

Snaking dislocation winding

Automatic strobe light

Electric width adjustment

Folding center position side shift

Online width measurement(Option)

Technical Parameter

| Applicable Material | For PVC\PETG\OPS Shrink Sleeve Label |

| Maximum Speed | 450 m/min |

| Maximum Product Width | 350 mm |

| Minimum Product Width | 30 mm |

| Maximum Unwind Width | 710mm |

| Maximum Unwind Diameter | Φ 500 mm |

| Maximum Rewind Diameter | Φ 900 mm |

| Diameter precision | ±0.4mm |

| Former Width Control – Adjust Minimum Range | electric: 0.1mm |

| Former Width Control – Left and Right Side Shift Range | electric: ±120mm |

Main Feature

1. The non-template mode has low scratch rate to materials, easy operation, and basically solves the problem of folding, shrinking, and cracking of traditional gassho machines.

2. The system has a high degree of maturity and is suitable for the production of process products. (We have done detailed optimization of each operating point: stable optimization of acceleration and deceleration state, optimization of convenience for workers to operate, alternatives to save labor in production, optimization of various intelligent automatic resets to reduce human operation, optimization of production loss, etc.)

3. Double pump and double gluing mode, which enhances gluing quality assurance.

4. Mature market applications, relatively high production indicators, reduce losses caused by manual errors.

5. Real integrated control development, single-point operation, good system coordination.

6. The intervention of the automatic width system can solve the problem that it is difficult to manually measure the real-time width during online production. With the motor width adjustment system, the size can be automatically adjusted to avoid a lot of losses due to negligence in production.

7. Full servo system, stable tension, less maintenance for long-term use of equipment.