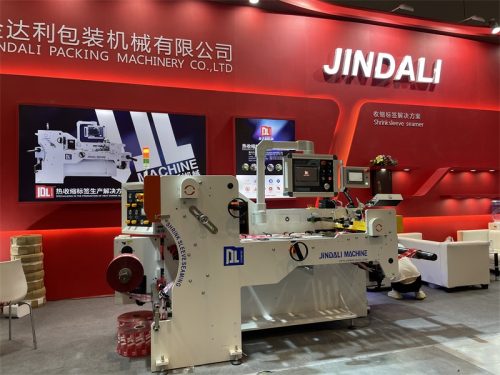

S300 High Speed Shrink Sleeve Seaming Machine - Template free

This is our enhanced model of High Speed Shrink Sleeve Seaming Machine. On the basis of the standard model, the maximum running speed of the machine has been upgraded, the unwinding width has been increased, and the motorized width control has been upgraded, allowing you to convert wider shrink labels faster.

System Function

Automatic unwinding tension

Automatic memory curve winding tension

Automatic glue supply control

automatic meter counter

The roll diameter reaches the stop

Unwinding correction

Snaking dislocation winding

Automatic strobe light

Electric width adjustment

Folding center position side shift

Online width measurement(Option)

Technical Parameter

| Applicable Material | For PVC\PETG\OPS Shrink Sleeve Label |

| Maximum Speed | 480 m/min |

| Maximum Product Width | 300 mm |

| Minimum Product Width | 30 mm |

| Maximum Unwind Width | 610mm |

| Maximum Unwind Diameter | Φ 500 mm |

| Maximum Rewind Diameter | Φ 900 mm |

| Diameter precision | ±0.4mm |

| Former Width Control – Adjust Minimum Range | electric: 0.1mm |

| Former Width Control – Left and Right Side Shift Range | electric: ±100mm |

Main Feature

Based on the main features of the G250 High Speed Shrink Sleeve Seaming Machine, the following aspects have been upgraded to meet your higher production needs:

PLC

power supply

Left and right forming wheel drive

Left and right bezel drive